Trends in Aseptic Flex Bag Market (2025-2035)

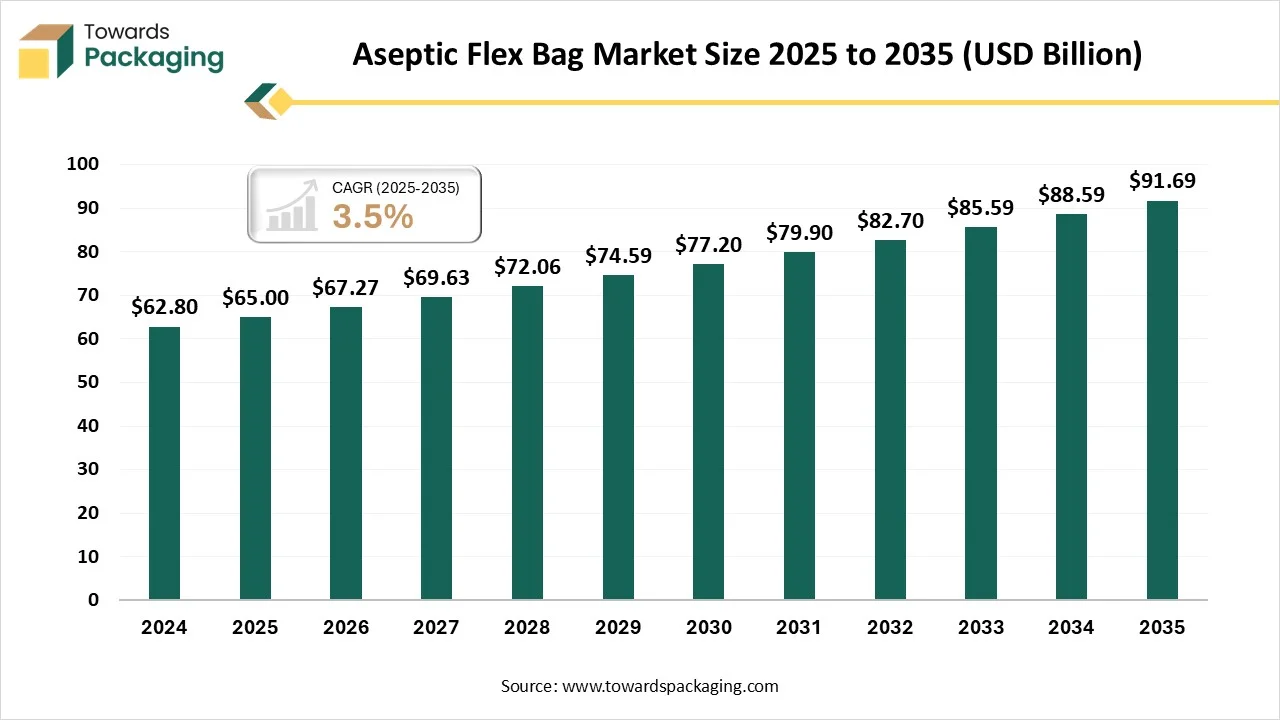

As detailed in the latest report by Towards Packaging, the global aseptic flex bag market is forecast to grow from USD 67.27 billion in 2026 to about USD 91.69 billion by 2034, at a CAGR of 3.5% between 2025 and 2034.

Ottawa, Dec. 02, 2025 (GLOBE NEWSWIRE) -- The global aseptic flex bag market, which stood at USD 65 billion in 2025, is projected to grow further to USD 91.69 billion by 2034, according to data published by Towards Packaging, a sister firm of Precedence Research. This market is growing due to increasing demand for safe, sterile, and long shelf-life liquid packaging across food, beverage, and pharmaceutical applications.

Request Research Report Built Around Your Goals: sales@towardspackaging.com

Key Insights

- North America has dominated the aseptic flex bag market, having the biggest share in 2024.

- Asia Pacific is expected to rise at a notable CAGR between 2025 and 2034.

- By type, the 2D bags segment has contributed the largest market share in 2024.

- By type, the 3D bags segment will grow at a notable CAGR between 2025 and 2034.

- By layer material, the polyethylene segment contributed the largest share in 2024.

- By layer material, the ethylene vinyl acetate segment will grow at a notable CAGR between 2025 and 2034.

- By application, the biopharmaceutical processing segment has contributed the largest market share in 2024.

- By application, the food & beverage segment will grow at a notable CAGR between 2025 and 2034.

- By end use, the pharmaceutical & biotechnology companies segment contributed the largest share in 2024.

- By end use, the contract manufacturing organizations segment will grow at a notable CAGR between 2025 and 2034.

Key Technological Shifts

| Technological Shifts | Description | Impact on Market |

| Advanced multilayer barrier films | Use of EVOH-, PVDC-, and aluminum-free high-barrier films to prevent oxygen and microbial intrusion | Enhances product shelf life and reduces the need for preservatives. |

| Automated Aseptic Filling Systems | Integration of robotics, closed-loop sterilization, and high-speed filling technologies. | Improves sterility, reduces labor costs, and increases production efficiency. |

| Smart Packaging & Sensors | Inclusion of temperature, pressure, and contamination sensors. | Enables real-time quality monitoring and reduces spoilage. |

| Sustainable Film Innovations | Development of recyclable, bio-based, and reduced plastic films. | Supports global sustainability goals and lowers environmental footprint. |

| Enhanced Sterilization Methods | Adoption of advanced techniques like H₂O₂ vapor, UV-C, and electron-beam sterilization. | Ensures higher sterility levels and compatibility with sensitive products. |

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5881

Market Overview

The aseptic flex bag market is witnessing rapid growth as businesses move toward sterile, contamination-free liquid and semi-liquid packaging options because they have a longer shelf life and drive adoption. Market expansion is further accelerated by the growing emphasis on economically sustainable and efficient packaging.

Market Outlook

- Industry Growth Overview: The aseptic flex bag industry is experiencing steady growth as manufacturers adopt sterile high-efficiency packaging to support rising demand in dairy, beverages, and pharmaceuticals. Increased investment in automated filling systems and enhanced barrier materials further accelerated market expansion.

- Sustainability Trends: Sustainability is shaping the market as companies shift toward recyclable films, reduced plastic usage, and lower carbon production processes. The push for eco-friendly lightweight packaging is encouraging wider adoption of aseptic flex bags over rigid formats.

-

Startup Economy: Global expansion is fueled by strong uptake in emerging markets and broader international supply chain adoption of aseptic packaging. Growing cross-border trade of liquid food products and pharmaceuticals is driving deeper market penetration worldwide.

More Insights of Towards Packaging:

- Cardboard Sheet Market Size, Segments, Share and Companies

- Pharma Blister Packaging Machines Market Drives at 2.85% CAGR

- PVC Packaging Film Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Germany Flexible Packaging Market Size, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- AI in Sustainable Packaging Market Size, Regional Share (NA/EU/APAC/LA/MEA) and Competitive Analysis

- Industrial Packaging Recycling Services Market Size, Segments, Share and Companies

- Pharmaceutical Composite Films and Bags Market Competitive Landscape & Future Outlook

- Consumer Goods Packaging Market Drives at 5.44% CAGR (2025-34)

- Smart Labels Market Size, Segments, Share and Companies

- Smart Corrugated Packaging Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade, 2025-2034

- North America Corrugated Packaging Market Growth, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

- North America Corrugated and Folding Carton Packaging Market Size, Value Chain & Trade Analysis 2025-2034

- Corrugated Bubble Wrap Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Temperature Controlled Packaging Solutions Market Size, Segments, Share and Companies

- Integrated Circuit Packaging Market Trends: SMT, Advanced Packaging, and AI Adoption

- Corrugated Sheet Board Market Drives at Strong CAGR (2025-34)

Segments Insights

By Type

The 2D bags segment dominated the aseptic flex bag market because it is widely used in the production of biopharmaceuticals. Many pharmaceutical and biotechnology companies have chosen it because of its simpler design, lower cost, and compatibility with current filling and storage systems. Furthermore, 2D bags are simpler to handle and sterilize, which strengthens their dominance in important production facilities around the world.

The 3D bags segment is growing rapidly in the market, driven by the growing need for packaging options that are more adaptable and compact. These bags are perfect for complex formulations and newer biologics because they provide improved flexibility between production protection and larger fill volumes. Adoption is speeding up, especially in areas with growing infrastructure for biopharmaceutical manufacturing.

By Layer Material

The polyethylene segment dominates the aseptic flex bag market because it is inexpensive, easily sterilized, and has outstanding chemical resistance because of its compatibility with a wide range of biopharmaceutical and food and beverage products. Aseptic flex bag manufacturers worldwide have come to rely on it.

The ethylene vinyl acetate segment is growing rapidly as producers look more and more for materials with higher performance, flexibility, and resistance to punctures. When compared to conventional polyethylene, EVA has superior mechanical strength and barrier qualities, which make it very appealing for new users in the food and biopharmaceutical industries.

By Application

The biopharmaceutical processing segment is dominating the aseptic flex bag market because sterile single-use systems are essential to produce pharmaceuticals. Aseptic flex bags are widely used for biologics storage, fermentation, and cell culture, assisting producers in lowering contamination risks and increasing operational effectiveness.

The food & beverage segment is growing rapidly. Aseptic flex bags are being used by manufacturers more frequently for the safe filling, transportation, and storage of liquid and semi-solid goods. This quick adoption is being fueled by rising demand for dairy products, juices, and ready-to-eat meals, as well as more stringent hygienic laws.

By End Use

The pharmaceutical & biotechnology companies segment is dominating the market, reflecting the high reliance on sterile, single-use solutions to ensure compliance and efficiency in drug production. These companies leverage aseptic flex bags for everything from upstream processing to final formulation storage.

The contract manufacturing organizations segment is growing rapidly, driven by outsourcing drug manufacturing continues to rise. CMOs increasingly invest in aseptic flex bag technologies to meet stringent client demands for sterility, flexibility, and rapid production scalability.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Regional Insights

The North America region dominates the market because of the early adoption of single-use technologies, robust regulatory frameworks, and well-established biopharmaceutical industries. The region's high R&D investment and sophisticated infrastructure sustain its market leadership.

U.S. Aseptic Flex Bag Market Trends

The U.S. leads the market due to early adoption of single-use technologies, stringent regulations, and sophisticated pharmaceutical and biotech industries. For biopharmaceutical processing, businesses frequently employ 2D and 3D aseptic bags to guarantee efficiency and sterility.

Asia Pacific is growing rapidly because of the quick growth of pharmaceutical production, growing healthcare spending, and rising biological demands. Aseptic flex bag systems are being adopted more quickly due and international production demands.

India Aseptic Flex Bag Market Trends

India is the fastest-growing market, driven by growing investments in healthcare, the pharmaceutical and food industries, and the use of single-use and 3D bags. Advanced layer materials such as EVA are becoming more widely used in order to satisfy increased quality and safety requirements. Market expansion is being accelerated by government programs that support domestic manufacturing as well as rising export demand.

Recent Developments in the Aseptic Flex Bag Industry:

- In July 2025, SIG launched the first 1‑liter aseptic carton pack made of SIG Terra Alu‑free + Full barrier material (world’s first full‑barrier aseptic 1 L carton without aluminium layer). The pack targets consumer convenience and environmentally friendly packaging solutions for liquid dairy and plant-based beverages.

- In June 2025, UFlex Limited announced the launch of a recycled‑PET single‑pellet solution for food & beverage packaging (in its packaging / aseptic‑packaging business portfolio). This initiative promotes circular economy practices while maintaining high barrier and safety standards for consumable products.

- In October 2025, POWTECH TECHNOPHARM 2025 (industry event) highlighted increased adoption of single‑use containment bags and flexible isolators (replacing traditional stainless-steel containers) for pharmaceutical/biopharmaceutical production, signalling a shift toward disposable flexible‑bag systems for aseptic / potent‑compound handling. These flexible systems help reduce cleaning and validation times while improving overall manufacturing efficiency.

Top Companies in the Aseptic Flex Bag Market & Their Offerings:

- Amcor plc: A global leader providing a broad portfolio of flexible and rigid aseptic packaging solutions, including bags, pouches, and bottles.

- Tetra Pak International SA: A major global provider of complete processing and packaging solutions, well-known for aseptic cartons and bags.

- SIG Combibloc Group AG: A leading solutions provider specializing in aseptic carton, bag-in-box, and spouted pouch packaging and filling systems.

- Scholle IPN (part of Graphic Packaging International): Specializes in flexible packaging and bag-in-box solutions for a wide range of liquid products.

- Greatview Aseptic Packaging Co., Ltd.: A global provider of sustainable and cost-effective aseptic carton packaging solutions.

- UFlex Limited: An India-based flexible packaging manufacturer with a dedicated aseptic liquid packaging brand called Asepto.

- ProAmpac: Offers a range of flexible packaging solutions, including pouches and bags for various markets, including food and pharma.

- Smurfit Kappa Group: A leading provider of paper-based packaging solutions, including sustainable bag-in-box products for liquids.

- Coveris Holdings S.A.: A European packaging company providing flexible packaging and high-performance films for multiple industries.

- Astor Plastics Pty Ltd.: An Australian company specializing in industrial packaging solutions, including bag-in-box systems.

-

DS Smith Plc: A leading provider of sustainable packaging solutions, including bag-in-box and other flexible options.

Segment Covered in the Report

By Type

- 2D Bags

- 3D Bags

By Layer Material

- Polyethylene

- Ethylene Vinyl Acetate

By Application

- Biopharmaceutical Processing

- Food & Beverage

By End Use

- Pharmaceutical & Biotechnology Companies

- Contract Manufacturing Organizations

By Region

North America:

- U.S.

- Canada

- Mexico

- Rest of North America

South America:

- Brazil

- Argentina

- Rest of South America

Europe:

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5881

Request Research Report Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram | Threads

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire | Globbook | Substack | Bluesky | - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Healthcare | Towards Auto | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

Towards Packaging Releases Its Latest Insight - Check It Out:

- Single Wall Corrugated Boxes Market Size & Share 2034

- Plastic Corrugated Sheets Market Size, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Volume-Optimized Corrugated Packaging Systems Market Size & Share

- Plastic Container Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Aerosol Cans Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Sharps Container Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Specialty Films Market Size, Regional Share (NA/EU/APAC/LA/MEA) and Competitive Analysis

- BOPP Films Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Recycle Ready Retort Pouches Market Size and Share 2034

- Aseptic Packaging Market Size, Share, and Forecast Analysis (2025-2034): Global Trends, Segments, and Regional Insights

- Agricultural Films Market Size, Segments, Share and Companies

- Plastic Aerosol Packaging Market – Size, Trends, Regional Insights, Competitive Landscape, Value Chain & Trade Analysis, 2024–2034

- Aerosol Packaging Market Size, Segments, and Regional Insights, Comprehensive Competitive Analysis (2025-2034)

- Ceramic Packaging Market Growth Opportunities, Emerging Trends & Major Players

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.